From the forge in Japan, the journey of a knife like no other.

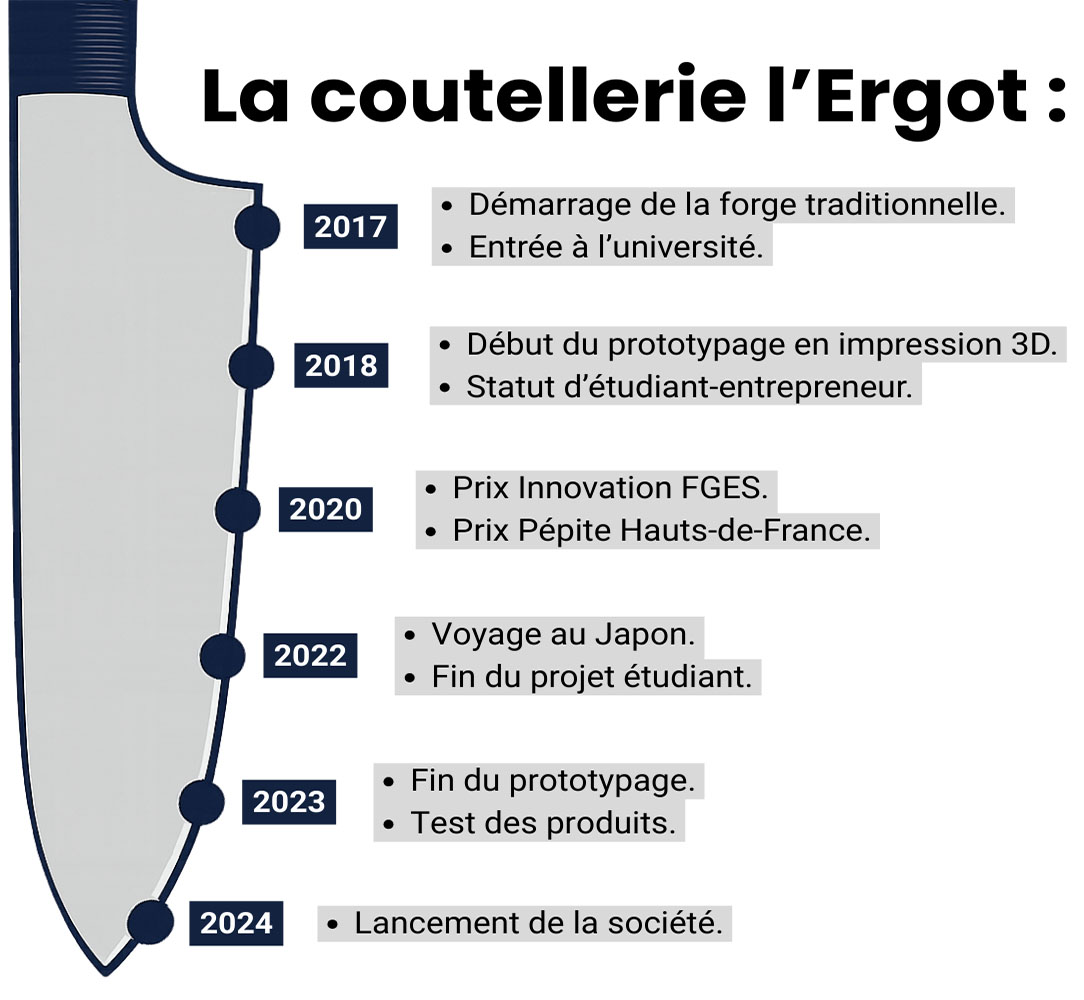

It all started in 2017, in an agricultural hangar, with a coal forge and ideas full of passion. For fun, I crafted simple, rudimentary knives, but already filled with passion.

The following year, I went to the University of Lille, my faculty got equipped with a metal 3D printer, and everything changed: I started designing blades directly in 3D printing, alongside my business management degree at FGES.

Quickly, the approach was appealing. I joined the faculty's incubator and obtained the status of student-entrepreneur, my creations won two awards:

- FGES Innovation Award 2019.

- Pépite Hauts-de-France Award 2020.

Driven by this momentum, I continued my studies at IESEG in a master's in international business, before joining Rikkyo University in Japan for an MIB. There, I discovered Japanese cutlery, its traditions, its pure lines, its demands.

On the way back, I stop in Thailand — that's where I meet the woman who will become my wife, then a chef de partie in a Japanese gourmet restaurant.

For her, I design my first truly personalized knives, conceived as unique, elegant, and functional gifts. The success is immediate.

From there, one thing becomes clear: these pieces deserve to be shared. That's how Coutellerie L'Ergot was born:

- 3D printed knives.

- Inspired by Japanese craftsmanship.

- Made in France.

- Designed to be gifted.

Your story and your journey:

Why did you start this company?

I created this company to revolutionize cutlery by combining tradition and innovation.

Thanks to 3D printing, we design high-performance, ergonomic, and customizable knives, with unmatched precision and durability.

Our mission is threefold:

- Make high-end knives accessible to beginners by offering reliable and easy-to-use tools.

- Offer a customizable and affordable gift, ideal for enthusiasts as well as those looking for a unique piece.

- Transform 3D printing into a true production method, allowing the creation of quality finished products, not just prototypes.

With this approach, we push the boundaries of manufacturing to offer innovative knives, both modern and rooted in cutlery expertise.

Where did this passion for knives and 3D printing come from?

Passionate about knives and innovation, I have always been fascinated by their design and evolution.

3D printing offers unprecedented creative freedom, allowing optimization of every detail for more efficient and customizable knives.

By combining these two worlds, I push the limits of traditional cutlery to offer unique and modern pieces.

How is this technology a revolution in cutlery?

3D printing in cutlery is a revolution because it allows for advanced customization, reduces production costs, and facilitates the creation of complex shapes that are otherwise difficult to achieve with traditional methods.

Moreover, it offers rapid prototyping and flexibility in small series production, while minimizing waste.

This opens up new possibilities for knife designers and manufacturers.